Americraft fans are standard built from carbon steel and coated with a super durable Polyester TGIC powder coating. While this is useful for typical environments, needing to resist heat and weather, some fans may need extra protection against corrosion. Our fans are also available in 304 and 316 stainless steel. Both provide more resistance against harsher materials, but sometimes 316 is for the most drastic environments.

The biggest difference between stainless and carbon steel is that stainless has Chromium added, which is the main source of its look and resistance and against corrosion and oxidation, along with increased resistance against more extreme temperatures. This added resistance makes 304 stainless a good choice for the food service such as appliances and liquid storage. The resistance to oxidation gives it the ability to be washed without getting rusty.

316 stainless steel has molybdenum added, along with chromium, to give it even more resistance against corrosion for a higher price. This becomes necessary in environments where it is necessary to prevent contamination such as processing food, brewing alcohol, and in the medical field from working with pharmaceuticals to implants. 316 is also much more resistant to salts, making it the optimal choice for facilities on a seacoast, or near a road that frequently gets snow and needs salting.

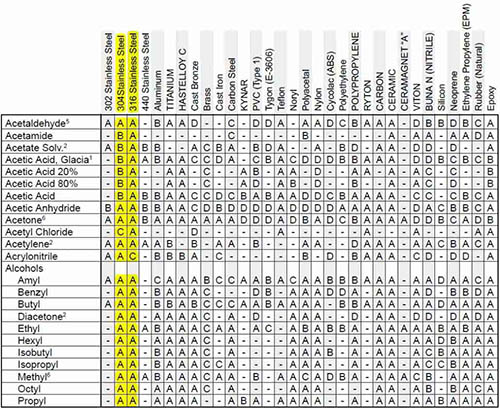

For most of your ventilation needs, Americraft has you covered. If you would like more information on the differences between 304 and 316 stainless steel, be sure to check out our sources and the charts comparing corrosive resistance (below).

Click image to view full chart (external PDF link)

Sources

https://www.upmet.com/sites/default/files/whitepapers/304-vs.-316-whats-the-difference.pdf

https://www.unifiedalloys.com/blog/304-316-stainless/

https://www.reliance-foundry.com/blog/304-vs-316-stainless-steel

https://arthurharris.com/news/304-vs-316-stainless-steel/

https://www.nemaenclosures.com/blog/304-and-316-stainless-steel/